Laser Texturing - Design Rendering Engineering

.

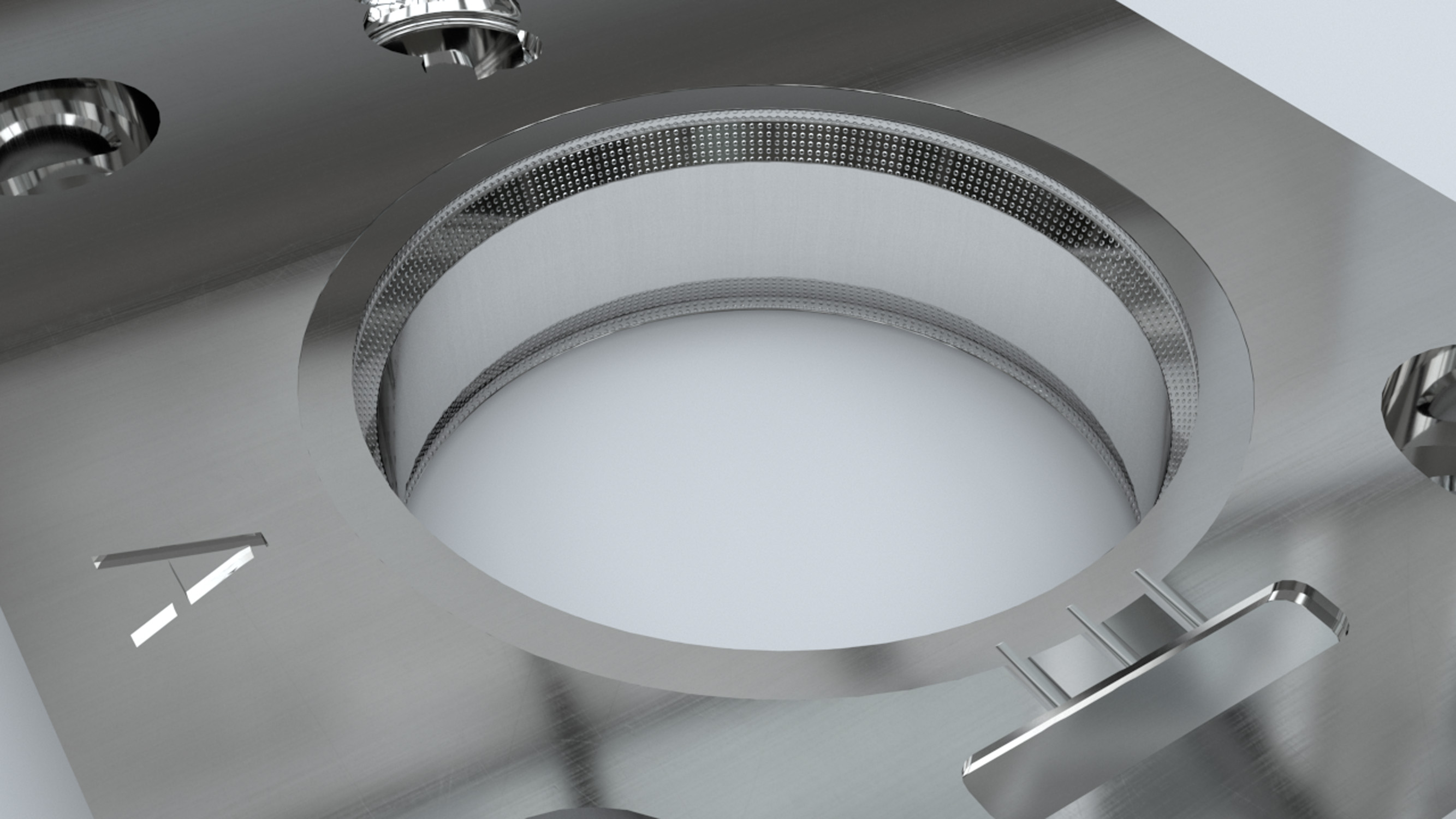

Laser texturing is a combination of high-technology and know-how. That's why the R&D Dept. of ML Engraving has developed the D.R.E® - Design Rendering Engineering, a revolutionary digital process that joins together the creative area along with the technical and productive areas. By means of D.R.E® every creative idea can be turned into a texture and laser engraved on moulds with the highest accuracy in every single detail. Laser texturing: the new frontier of product design.

The D.R.E® - Design Rendering Engineering project starts up in 2005 after in-depth studies of the R&D Dept of ML Engraving, in order to improve the laser texturing service on moulds.

Today D.R.E® represents the heart and soul of ML Engraving and it has let to a revolution in the world of textures, that is the complete digitation of the process from planning to laser engraving.

The development of D.R.E® - Design Rendering Engineering has required the application of a variety of softwares, that come from digital animation, special effects and 3D modelling . ML Engraving has elaborated technical solutions that can be combined with its technology and that have made it possible to engrave 3D textures with laser, from geometric to natural ones, on every king of metal surfaces.

By means of D.R.E® - Design Rendering Engineering, ML Engraving is able to:

- engrave 3D textures with laser on every surface, even the most complex,

- create an Executable Rendering to be sent to the CNC machine,

- check every step of the working process,

- map the file texture on the file body of the mould and check deformations, seams and distortions,

- avoid down times: the digital file is prepared while the mould is still under construction.