Friction Theory and Experiments

.

The Institute of Dynamics and Vibration Research (IDS) is part of the Leibniz University Hannover, Germany. The research group Friction and Tribology focusses on the investigation of elastomer friction and wear, which occurs in tire/road and dynamic seal contacts. The work of the research group is both based on experiments and on theory/modelling.

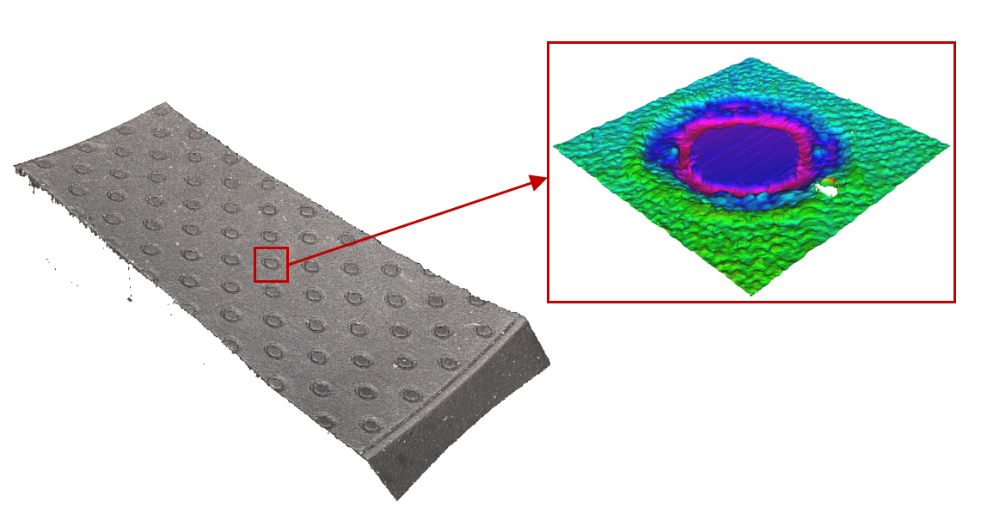

Improved friction behaviour is an important design objective in the development process of dynamic sealing systems. Surface texturing of dynamic seals is one possibility to reduce friction and wear without changing key parameters such as the material or lubricant properties. The texture is applied to the seal surface in the form of deterministic dimples and a microscopic surface roughness (Fig. 1). The major challenge related to this technology is the determination of optimal textures with the greatest friction reduction under various operating conditions.

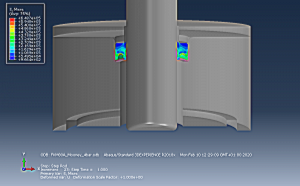

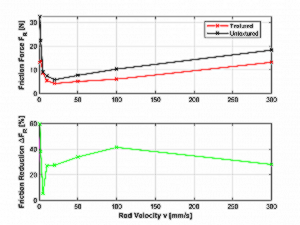

In order to select optimal surface textures, the IDS offers a large range of test rigs, which are used in the project to measure the friction forces of both translational and rotational seals (Fig. 2). The experiments on prototype seals provide reliable results for friction reduction of different textures as well as for the validation of numerical simulations. The mixed friction simulation model developed during the project is used to understand the underlying friction mechanisms of surface textured seals and to predict the friction forces of dynamic seals as a function of texture and operating conditions (Fig. 3). The desired output variable of the experiments and the numerical simulations is the percentage friction reduction, which represents a significant value for increasing the energy efficiency of the tribological system (Fig. 4).

Relevant representative references

- S. Bothe, M. Wangenheim, Application of a Multi-Scale Hysteresis Friction Model to Aircraft Tires During Landing, Proceedings International Mechanical Engineering Congress & Exposition 2017, 2017. DOI: 10.1115/IMECE2017-71241

- S. Kahms, M. Wangenheim, “Experimental Investigation and Simulation of Aircraft Tire Wear”, Tire Science and Technology, im Druck, 2020.

- M. Zimmermann, M. Wangenheim, “Friction behaviour of surface textured elastomeric seals in pneumatic actuators”, Proc. 23rd International Conference on Fluid Sealing, Manchester (UK), 2016.